NET-0 Egg Barn Blog – Raise the Roof

Net-Zero Egg Barn, Blog Post #2 – Raise the Roof: September 15/2015

Brant Colony made tremendous progress over the summer, completing the construction of the external structure in a little over two months. With the roof in place, the Net-0 facility is starting to resemble a barn. There are just a few outstanding items to be added, before the exterior tin sheeting can be installed.

Those six portal openings on the end of the building (layer barn) are for the ventilation system – no, they aren’t fancy windows – and there are identical openings at the opposite end of the building (pullet barn). The three square openings are for the large 54” fans, and the three octagonal openings are for smaller variable-speed fans.

Those six portal openings on the end of the building (layer barn) are for the ventilation system – no, they aren’t fancy windows – and there are identical openings at the opposite end of the building (pullet barn). The three square openings are for the large 54” fans, and the three octagonal openings are for smaller variable-speed fans.

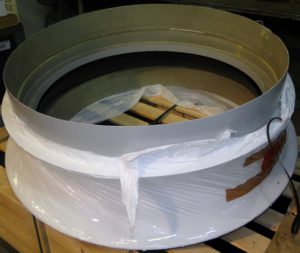

One of the key features that contributes to the Net-0 design is the Heat Recovery Ventilator (HRV), which will be the first of its kind to be installed in an Alberta egg farm. The HRV unit will be 40’ long when fully assembled, and will sit outside the barn at about the midway point.

Thankfully the HRV came with instructions! An expert will also be on-site to help with the installation!

The barn interior is heated through aluminum strips, which have tubes for heated water to flow through, effectively heating by emanating/diffusing heat from the surface of the strips.

Energy efficient construction begins with the foundation and the exterior walls. The barn interior has 6” thick cement floors with a vapor barrier underneath it, which sits on 3-4” of drainage rock. Both the office area and manure room have 6” thick cement floors with in-floor heating underneath it, which sits on 1.5” of insulation.

The exterior stud walls were built using 2″ x 8″ boards, to allow for extra insulation to be added.

Styrofoam insulation was installed on both sides (interior & exterior) of all exterior walls, which extends down 4’ into the ground, below the frost line. Only the exterior side remains visible, as the interior side was encased in cement.

Venturing inside the barn, the attic is divided into thirds (two sections above the layer barn and one section above the pullet barn), with smoke stops between the sections. There will also be 14” of insulation in the ceiling.

This isn’t quite a birds-eye-view, but here’s the view from the center of the Net-0 facility, in the middle of September.