NET-0 Egg Barn Blog – Egg Collection

Net-Zero Egg Barn, Blog Post #7 – Egg Collection: April 29/2016

Having an efficient egg collection strategy is critical for every layer operation, to ensure that they contribute to providing a stable supply of fresh, locally produced eggs for all Albertans.

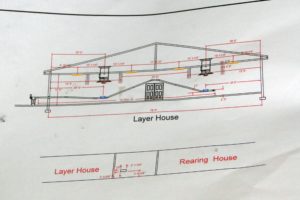

Before construction even began, the design had to be just right, including the placement of the egg belts running the length of the hen housing structures, the route for the egg collection conveyor, the location for installing the egg packing machine, and the energy-efficient egg cooler.

The small opening below shown both, from the hallway and the egg collection room in the office area during our visit in September 2015, will be the final step in every egg’s journey from the layer barn to the packer. The picture on the right shows where the egg cooler will be located, along with the cooler door, where pallets of eggs will be loaded onto trucks destined for the grading station.

By the time we visited again in November, the interior construction was almost complete. That’s the hallway between the layer barn and pullet barn. Brant Colony’s egg manager, Darrel, showed us plans for the egg belt, which still required a lot of assembly. Darrel was already looking forward to collecting eggs with his new egg packer!

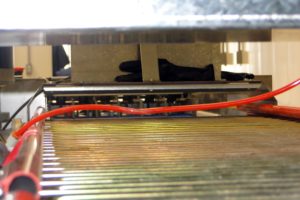

By January 2016, the egg belt was fully assembled. To help protect the eggs, the belt is covered from the layer barn into the hallway.

Eggs are gently transferred from the two egg belts onto a single egg conveyor, where they’re taken into the egg collection room, through the small opening. You’ll notice that Darrel decided to add a big window above the opening, so he’ll be able to monitor the egg conveyor in the hallway, as the eggs are packed in the collection room.

Darrel was excited to demonstrate his impressive egg collection process during our visit in April. Every step of the egg’s journey from the layer barn was clean, quiet and efficient!

The egg collection wouldn’t be complete without having an appropriate place to store the eggs, until the grading station comes to pick them up. The large cooler can store many pallets of eggs, and both the temperature and humidity are monitored, to ensure the cooler operates in accordance with requirements set by the Canadian Food Inspection Agency. Darrel is proud to share the eggs laid by the hens who call Brant Colony’s net-zero egg barn home!